Key Takeaways

- Integration of Traditional and Modern Techniques: Mechanization drawing combines traditional drafting methods with advanced technology, enhancing precision and efficiency in engineering and design.

- Collaboration and Real-Time Sharing: This technique promotes better collaboration among teams, allowing for real-time modifications and feedback, which streamlines the production process.

- Applications Across Industries: Mechanization drawing is vital in various sectors such as architecture, manufacturing, construction, and automotive, improving accuracy and minimizing errors in project execution.

- Advanced Tools and Software: Utilizing modern software solutions like CAD and BIM significantly enhances the ability to create intricate designs and supports innovation while reducing manual errors.

- Challenges to Address: High initial costs, software complexity, and a dependency on technology present challenges in adopting mechanization drawing, necessitating strategic management to mitigate these issues.

- Future Trends: Emerging technologies, including AI, cloud platforms, and immersive tools like VR/AR, are set to revolutionize mechanization drawing, fostering greater efficiency, collaboration, and sustainability in design practices.

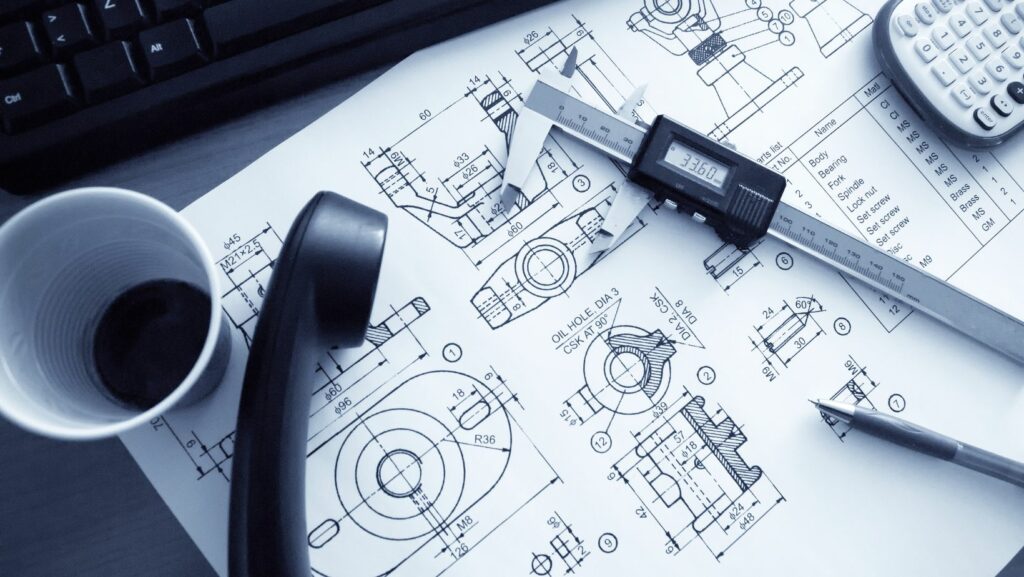

In an era where technology reigns supreme, mechanization drawing stands out as a pivotal tool in engineering and design. This technique merges traditional drafting with modern technology, allowing for precision and efficiency in creating complex designs. As industries evolve, understanding the nuances of mechanization drawing becomes essential for professionals looking to stay ahead.

From architecture to manufacturing, mechanization drawing simplifies the visualization of intricate components and systems. It enhances collaboration among teams and streamlines the production process. As the demand for accuracy and speed increases, mastering this skill can significantly impact project outcomes and innovation. Exploring the principles and applications of mechanization drawing reveals its vital role in shaping the future of design and engineering.

Mechanization Drawing

Mechanization drawing represents a significant advancement in engineering and design. This method integrates traditional drafting techniques with contemporary technology, enhancing both precision and efficiency. Professionals utilize specialized software and tools to create detailed and accurate representations of designs.

Mechanization drawing improves collaboration across various industries, including architecture and manufacturing. Sequential iterations allow teams to share and modify designs in real time, facilitating feedback and reducing communication barriers.

The use of mechanization drawing satisfies the growing demand for accuracy and speed in project execution. It enables professionals to produce high-quality outcomes while meeting tight deadlines. As industries shift towards more complex projects, mastering mechanization drawing becomes essential.

The broader implications of mechanization drawing impact the future of design and engineering. Its application promotes innovation, encourages sustainable practices, and streamlines workflows. As technology continues to evolve, mechanization drawing will likely play a pivotal role in shaping the next generation of engineering solutions.

Importance of Mechanization Drawing

Mechanization drawing plays a vital role in engineering and design, serving as a bridge between traditional methods and cutting-edge technology. Professionals rely on this technique to enhance accuracy, efficiency, and collaboration across diverse sectors.

Benefits in Various Industries

Architecture: Mechanization drawing facilitates the creation of precise plans and elevations. It enables architects to visualize structures in 3D, enhancing client presentations and project reviews.

Architecture: Mechanization drawing facilitates the creation of precise plans and elevations. It enables architects to visualize structures in 3D, enhancing client presentations and project reviews.- Manufacturing: Engineers utilize mechanization drawing for designing components. This usage ensures parts fit together seamlessly during assembly processes, reducing errors and costs.

- Construction: Construction professionals depend on detailed mechanization drawings for accurate planning. These drawings help in coordinating materials, labor, and timelines, streamlining overall project execution.

- Automotive: In the automotive industry, mechanization drawing enables detailed modeling of vehicle components. This detailed representation fosters innovation and enhances safety through rigorous testing simulations.

- Collaboration: Mechanization drawing promotes real-time sharing among team members, allowing for immediate feedback. This improves communication and speeds up decision-making processes.

- Precision: Automated tools in mechanization drawing reduce manual errors, ensuring that designs are executed as intended. High precision leads to fewer revisions during the design and production stages.

- Efficiency: Advanced software streamlines repetitive tasks, boosting productivity. Rapid adjustments and modifications contribute to time savings and efficient resource management.

- Innovation: The integration of mechanization drawing with automation encourages creative solutions. It provides designers and engineers with the flexibility to experiment with new ideas without significant delays.

Tools and Technologies in Mechanization Drawing

Mechanization drawing relies on a combination of traditional tools and modern software solutions. These instruments enhance the ability to create intricate designs while improving accuracy and collaboration.

Traditional Tools

Traditional tools play a foundational role in mechanization drawing. These include:

- Drawing Boards: Provide a stable surface for hand-drafting designs.

- T-squares: Help maintain straight lines and ensure accurate measurements.

- Compasses: Facilitate the creation of precise circles and arcs.

- Scales: Allow for proportional measurements, essential for translating designs accurately.

- Mechanical Pencils: Offer consistent line thickness for detailed drawings.

These tools support the initial stages of design, allowing professionals to visualize concepts before transitioning to digital formats.

Modern Software Solutions

Modern software solutions revolutionize mechanization drawing by introducing advanced features that enhance efficiency. Key software includes:

- Computer-Aided Design (CAD): Enables 2D and 3D modeling, offering detailed design capabilities.

- Building Information Modeling (BIM): Integrates various aspects of building design, fostering collaboration among architects and engineers.

- Simulation Software: Provides analysis of designs through virtual testing, identifying issues before physical production.

- Collaboration Platforms: Facilitate real-time sharing of designs, improving teamwork and project outcomes.

These solutions streamline the design process, ensuring high levels of precision while accommodating rapid changes in project requirements.

Applications of Mechanization Drawing

Mechanization drawing plays a vital role across various industries, driving improvements in accuracy, efficiency, and collaboration. This section highlights specific applications and case studies that showcase its impact in engineering and architecture.

Case Studies in Engineering

- Automotive Manufacturing: Leading manufacturers like Ford utilize mechanization drawing to design complex vehicle components. Simulation software allows for rigorous testing, reducing design flaws and enhancing safety. This method also streamlines the production process, resulting in shorter manufacturing times and lower costs.

- Aerospace Engineering: Companies such as Boeing apply mechanization drawing for precise modeling of aircraft systems. By employing CAD tools, engineers develop detailed assemblies that optimize aerodynamics and structural integrity. This approach significantly decreases the risk of errors during assembly and enhances compliance with safety regulations.

- Civil Engineering: Firms like Ove Arup & Partners leverage mechanization drawing for infrastructure projects. Detailed drawings assist in visualizing project requirements and coordinating with multiple stakeholders. This methodology decreases construction delays, ensuring projects stay within budget and schedule constraints.

- Building Design: Architects utilize mechanization drawing to produce detailed plans that incorporate both aesthetic and functional elements. Tools like BIM enable the creation of 3D models, allowing for more effective communication with clients. These drawings also facilitate effective modifications, helping to meet specific client needs.

- Urban Planning: Cities like Barcelona employ mechanization drawing in their urban design initiatives. Accurate representations of city layouts improve public transportation systems and resource management. This technique supports sustainable practices by optimizing land use and infrastructure development.

- Renovation Projects: In renovation scenarios, detailed mechanization drawings provide architects a clear view of existing structures. This clarity aids in designing compatible upgrades and modifications. Accurate depictions help in assessing structural integrity, allowing for safer renovations that honor historical context.

Challenges and Limitations

Mechanization drawing presents several challenges and limitations that can impact its effectiveness in various projects.

High Initial Costs

High initial costs for advanced software and hardware can be a barrier for smaller firms. They require a significant investment in tools and training for staff, which may deter some from adopting mechanization drawing techniques.

Software Complexity

Software complexity can hinder productivity. Many professional-grade applications come with steep learning curves, demanding extensive training. Users may struggle to fully utilize the software’s capabilities, compromising efficiency.

Dependency on Technology

Dependency on technology often leads to issues when systems fail. Technical glitches or power outages can disrupt workflows. Such interruptions may cause delays in project timelines and impact collaboration.

Data Management Challenges

Data management challenges arise from the vast amount of information generated. Ensuring accuracy and organization can be difficult, particularly in large projects. Projects may face setbacks due to misplaced or outdated files.

Integration Issues

Integration issues may occur when blending mechanization drawing with existing systems. Different platforms might not communicate seamlessly, complicating the collaboration process.

Limited Creativity

Limited creativity can emerge from reliance on automation. While mechanization drawing enhances precision, it may stifle innovative design approaches. Designers might become overly focused on software capabilities rather than exploring unconventional ideas.

Skill Gap

Skill gaps among personnel can pose significant hurdles. Not all professionals possess the necessary training in advanced drawing techniques. This disconnect can affect team collaboration and the quality of output.

Regulatory Compliance

Regulatory compliance requirements can complicate mechanization drawing efforts. Adhering to local regulations and standards requires diligence and may slow down the design process.

These challenges highlight the need for careful consideration when implementing mechanization drawing in engineering and design. Addressing these issues can cultivate a more efficient environment and enhance project outcomes.

Future Trends in Mechanization Drawing

Future trends in mechanization drawing emphasize technology integration, automation, and collaborative advancements. The emergence of artificial intelligence (AI) is transforming design processes, allowing systems to generate design options based on parameters set by professionals. AI tools accelerate decision-making and enhance creativity by providing predictive analytics and optimization suggestions.

Future trends in mechanization drawing emphasize technology integration, automation, and collaborative advancements. The emergence of artificial intelligence (AI) is transforming design processes, allowing systems to generate design options based on parameters set by professionals. AI tools accelerate decision-making and enhance creativity by providing predictive analytics and optimization suggestions.

Cloud-based platforms for mechanization drawing are gaining traction, enabling seamless sharing and collaboration among stakeholders, regardless of location. These platforms facilitate real-time feedback and modifications, enhancing communication and productivity. Teams can view updates instantly, ensuring that everyone works with the most current information.

Sustainability becomes a central focus in future design practices. Mechanization drawing tools increasingly incorporate features that assess environmental impact, enabling professionals to design more eco-friendly solutions. This trend drives the industry towards reducing waste and energy consumption while fostering innovative approaches to resource management.

Additionally, virtual reality (VR) and augmented reality (AR) play a pivotal role in enhancing mechanization drawing. These immersive technologies allow stakeholders to visualize designs in a three-dimensional space, improving understanding and engagement during the design phase. The ability to experience designs firsthand before construction accelerates problem identification and resolution.

BIM continues to evolve, integrating more advanced features that support interdisciplinary collaboration. Enhanced interoperability between tools improves data exchange, allowing architects, engineers, and contractors to work more efficiently. This trend pushes projects towards more integrated workflows, ultimately leading to faster and more cost-effective outcomes.

Automation is also shaping the landscape of mechanization drawing. Robotic systems and advanced software automate repetitive tasks, increasing efficiency and minimizing human error. As a result, professionals can allocate more time to strategic thinking and innovative aspects of design.

Finally, the integration of advanced data analytics enables the assessment of historical project outcomes to inform future designs. By analyzing previous data, teams can identify patterns, improve workflow, and better estimate project timelines and costs.

These emerging trends point towards a future where mechanization drawing becomes an even more indispensable part of design and engineering disciplines. With advancements in technology, the potential for improved efficiency, collaboration, sustainability, and creativity becomes boundless.

Engineering and Design

Mechanization drawing stands as a transformative force in engineering and design. Its blend of traditional methods with cutting-edge technology fosters enhanced accuracy and collaboration across various sectors. As industries evolve, the demand for precise and efficient design processes only grows stronger.

The challenges associated with mechanization drawing underscore the importance of strategic implementation. By addressing these obstacles, professionals can fully harness its benefits. With the rise of AI, cloud-based solutions, and advanced analytics, the future of mechanization drawing promises even greater innovation and sustainability. Embracing these advancements will empower designers and engineers to push the boundaries of creativity and efficiency in their projects.